Wind turbine components manufacturing

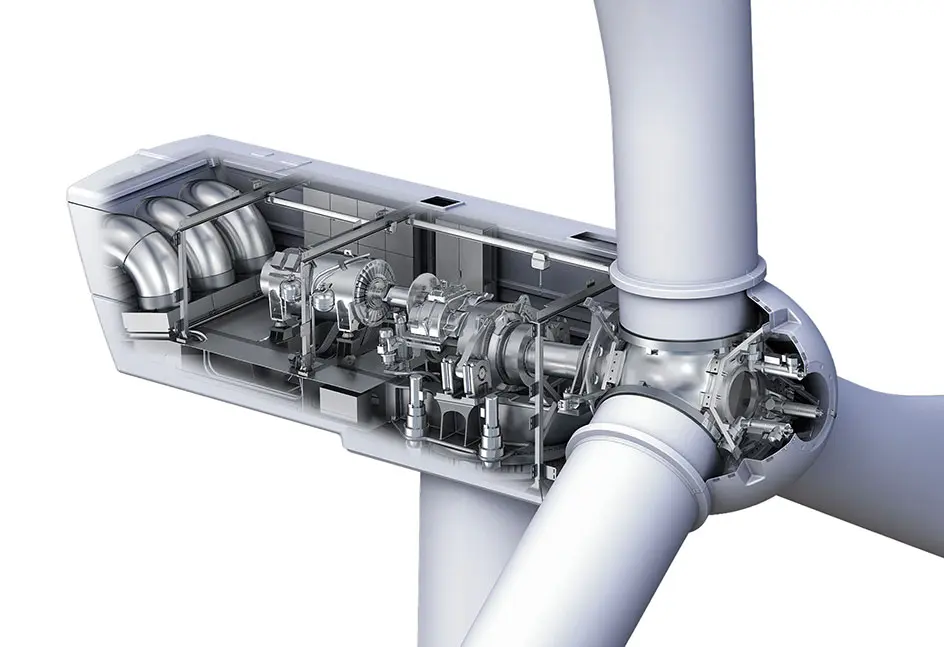

The interior structural architecture of modern wind turbines creates an exceedingly complicated mechanical and electrical system. The interior of the tower is made up of welded structural sections, with platforms positioned on various levels. The structures are mostly built of structural steel, with a hot-dip galvanized finish to ensure weather protection. Our skilled staff is able to mass-produce structures of diverse forms and sizes while adhering to rigorous quality standards and fulfilling delivery schedules.

Wind turbine interiors are also constructed from more complicated, bigger welded structural components that are then modularly connected with other large turbine components during final assembly. The constructions are already more sophisticated and durable, weatherproofed with a hot-dip galvanized coating, but there are also aluminum components and fasteners with a specific coating. Our expert team also executes product pre-assembly and packaging.

Our Capabilities

Futuretech provides you with the advantages of dealing with a full-service Wind Turbine Components supplier. Among our capabilities are the following:

- Rotor Pole Bridge & Clampings

- Clamping Bar

- Yaw claw upper part

- Transmission Gear Housing

- Gear Boxes

- wedge base frame stator LP4

- coupler stator finger plate

Why We Are the Right Supplier

In an advanced, heavy equipment business like Wind Turbine , you need a reliable source. When you choose Futuretech Engineers, you get the following benefits:

- Futuretech Engineers creates Wind Turbine components like Rotor Pole Bridge & Clampings, Clamping Bar, Yaw Claw Upper Part, Transmission Gear Housing, Gear Boxes, Wedge Base Frame Stator LP4, Coupler Stator Finger Plate . Our Components have the benefit of compact design and efficient energy conversion. Above all, they represent operational dependability, maximized energy yields and reduced downtime.

- Because we produce all important components in-house, we have complete control over quality standards.